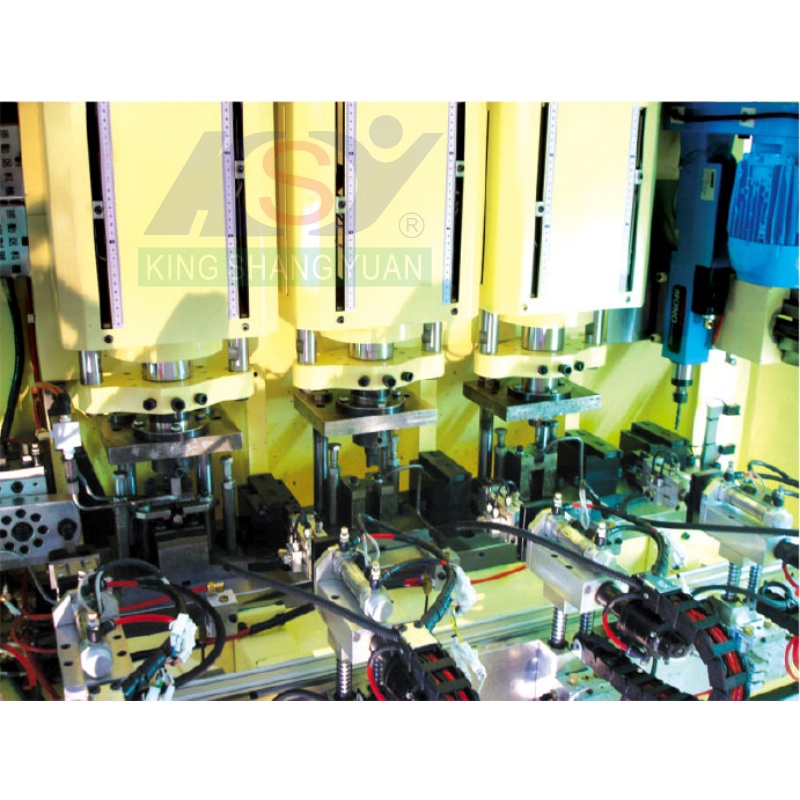

Multi-stage Automatic Press

Description

Multi-stage Automatic Press Machine Characteristics

- Multi-stage Automatic Press Machine with low energy consumption, less consumable parts and low noise level.

- High speed, high output, high efficiency.

- Easy precise adjustment of Oil pressure, head punch location, and lower dead point.

- Add on accessories: safety light curtain, die clamp, robot arm, and feeder.

- Control mold: Auto PLC control, buttons operated by both hands simultaneously, head punch home-return on hands-off, double pressing prevention.

- Multi-stage Automatic Press Machine can be using as individual operation equipment or one of the serial automatic manufacturing system.

- Safety operation by both hands simultaneously, head punch returns to orignal position as soon as hands off, time delay between two hands are less than 0.3 seconds.

Applications

- Tubing enlarging and reducing.

- Punching, stamping, forming, and cutting.

- Drawing, bending.

- Riveting, piercing, typing.

- Thin plate shearing, shear through and/or half.

- Components inserting, such as anti-vibrating nut.

Specifications subject to change based on R&D results without notice.

Standard specification are based on actual machine.

Patented product, pirating and counterfeiting are prohibited.

Multi-stage Automatic Press Machine Characteristics

|

Applications

|